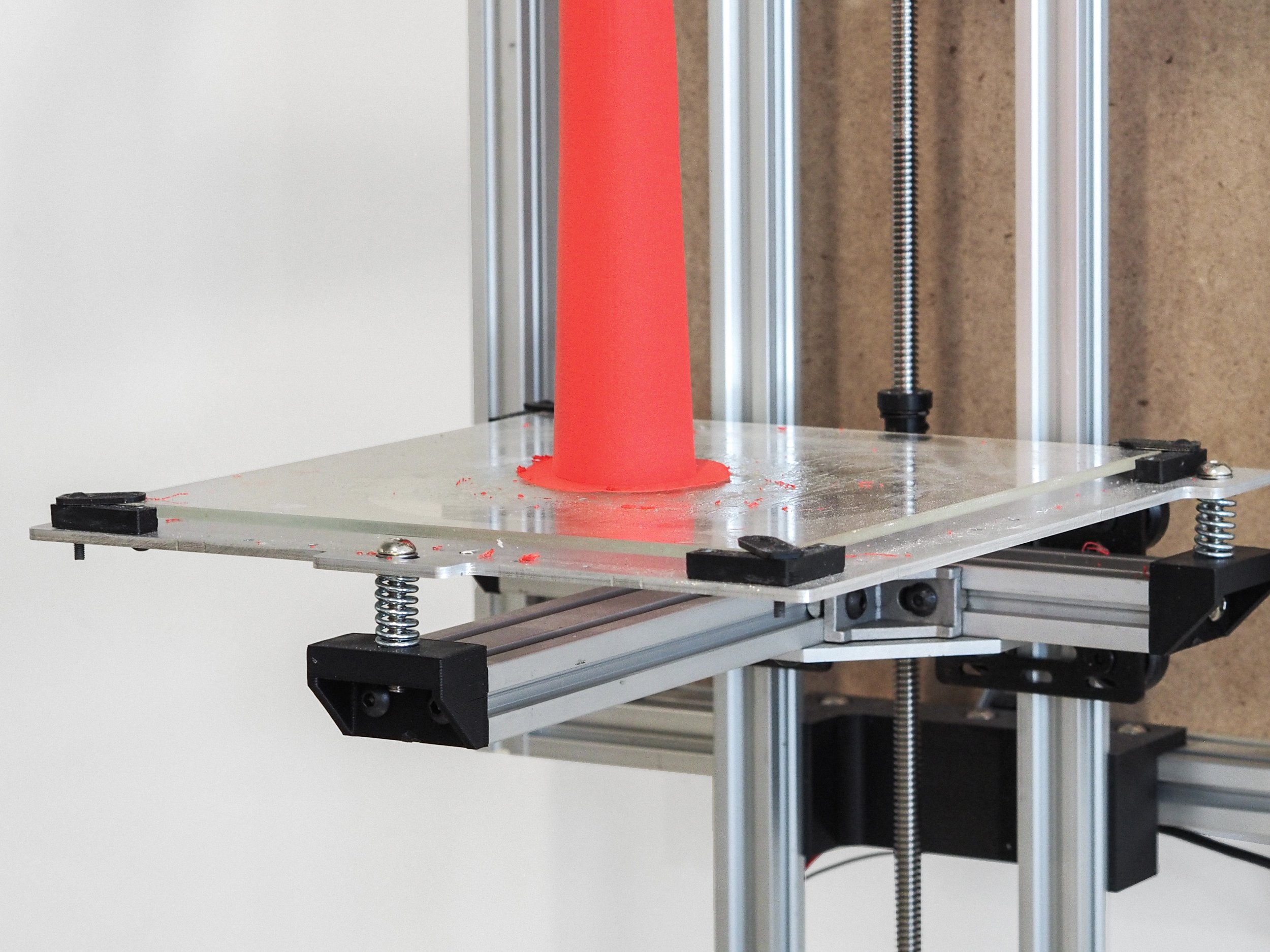

Process. 3D Printing

Could you print a bike with a desktop 3D Printer? Sure—but probably not one you’d like to ride. Although 3D printing is fundamental to our design process, there are no 3D printed components included in July frames. We use 3D printing solely to produce the patterns, molds, mandrels, and fixtures that shape carbon fiber into its final form.

In the production of a single frame, we utilize several consumer-grade FDM and SLA printers, alongside purpose-built equipment capable of producing mandrels and molds up to a meter in height. These tools, and the wide-ranging thermoplastics/resins they print, allow us to produce the complex frame components and unique tube shapes that make our frames truly custom.